Digital twin technology is a fascinating new concept, particularly when applied to the aviation industry. Rapidly gaining popularity among aviation industry professionals, it allows users to create a data-driven virtual replica of aircraft systems, mirroring the real-world counterparts and allowing operators to introduce smarter operating practices without risking damage to an expensive aircraft.

Digital twinning in helicopters is a natural progression of this innovative technology, allowing operators not only to develop smarter designs but also to enhance aspects such as predictive maintenance and operational efficiency.

In this article, we’ll take an in-depth look at the concept of digital twin technology and examine its relationship to the industry, both now and in the future. We’ll discuss the benefits and its uses, as well as how it’s currently being utilised within the sector, such as the Airbus Skywise system. We’ll also investigate how digital twin examples segue into existing Augmented Reality systems, such as FlySight’s OPENSIGHT platform, in the future. Let’s begin by defining what digital twinning technology is.

What is digital twinning in the aviation industry?

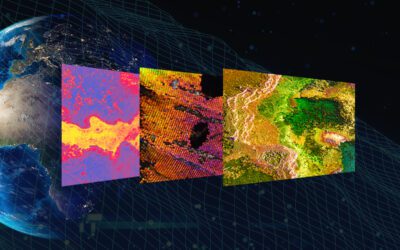

A digital twin is a virtual model of a physical object or asset. This could be an engine or sections of an aircraft. These models are continually updated using real-time input from sensors, combined with other information from simulations or records. It superimposes these together to give you a ‘digital twin example’ of the original, which can then be studied, altered, and revised to enhance operational efficiency, identify flaws or safety issues, and develop newer, more diligent methodologies around operational procedures, safety, and maintenance.

Through the use of machine learning algorithms, this virtual model provides an ideal platform for in-depth analysis, creating and responding to predictive scenarios, examining system behaviour (especially in adverse conditions), and developing new operating approaches.

The application of digital twin technology in aviation has led to significant advances in forecasting capabilities, fleet management, advanced diagnostics, and operational performance. Although it is still in its early stages, the technology currently being used has already demonstrated the significant advantages of digital twinning in the aviation sector.

How does it differ from traditional simulation technology?

The biggest difference is that while traditional simulations tend to be static and scenario-based, digital twinning is a dynamic diagnostic system that can be observed in real time. That makes it much more flexible as a diagnostic, training, or operational tool, one that doesn’t rely on pre-assumed parameters but can be adapted according to real-time data from active sensors. And while traditional simulation systems are somewhat limited to preset parameters, digital twinning is adaptive. It can respond to new information, absorbing it into the matrix and integrating it in real-time.

The benefits of using digital twin technology in aviation

Digital twin technology is especially valuable in aviation maintenance, providing excellent support for both scheduled and unscheduled maintenance. It allows technicians to study the performance of components and systems without grounding an aircraft or unnecessarily adding to the maintenance schedule. A digital twin serves as a testing ground for preventive and predictive maintenance, which can then be applied to operational aircraft. This reduces fault-finding, enables teams to plan maintenance schedules with greater accuracy, and allows them to experiment with new methodologies in a safe ‘virtual’ environment before applying them to the aircraft itself.

This approach, where processes are fine-tuned on the digital twin before being applied to the operational aircraft, helps reduce unnecessary costs and operational downtime, as well as ensuring a more comprehensive maintenance schedule that uses the latest best-practice methods and processes.

The same approach can be applied to creating operational systems. By using digital twinning technology before a system goes ‘live’, any bugs, inconsistencies, or inefficient elements can be ironed out. This enhances the safety of the aircraft and its crew by ensuring that all operational systems have been thoroughly tested on the digital twin before being implemented in the aircraft’s infrastructure. It also keeps R&D costs down and allows technicians to reassess, revise and redesign as necessary while keeping time and costs to an acceptable level.

Training is another area where a digital twin example can play a significant role. Simulators are already used to train pilots and operators. However, these rely on preset programs, which can become predictable. Introducing aviation digital twinning means that a pilot can train on the exact aircraft they will be operating, giving them more of a ‘feel’ for the nuances of that particular aircraft and familiarising them with its systems.

It can also introduce a more flexible training program with responses that are far more akin to the actual ‘real-life’ aircraft, and the input of the trainee. Even experienced pilots can benefit from training sessions on digital twins, which improve situational awareness and familiarise them with upgraded technology and new inclusions, such as Enhanced Reality consoles and AI-based software. This enables the creation of realistic dashboard simulations, in-flight diagnostic processes, and more. This virtual prototyping process enables a smoother and more focused transition from concept to reality, with invaluable input from the individuals who will actually use the systems in real life.

Digital twin technology in action

Digital twinning technology in aviation is already making its presence felt. The Airbus SkyWise system is a typical operational example, developed by Airbus in partnership with Palantir Technologies. SkyWise is effectively a ‘central nervous system’ for aircraft operations, introducing many of the applications we have previously mentioned. Using ‘big data’ principles, it creates a virtual ecosystem that allows processes such as predictive maintenance schedules to be drawn up and tested on a digital version before being applied to operational aircraft.

Rolls-Royce are also adopting digital twinning examples, using data collected from operational engines that is continually relayed back to a digital twin to examine engine efficiency and optimisation. Using this data, developers can identify ways to improve turbine efficiency, discuss issues such as microcracks, and develop preventative methods to eliminate them, as well as more accurately determine when the operational engine will require routine maintenance.

These applications can be used in any type of aircraft, including helicopters. The technology already exists to incorporate digital twinning in helicopters, with consoles such as FlySight’s OPENSIGHT offering a perfect platform for integrating this AR technology.

The challenges of digital twin technology in aviation

On the surface, digital twinning in aviation is a ‘no-brainer’. However, there are still challenges that need to be addressed, including the cost of setting up such a system and whether data integration will be as easy as initially predicted, or if there may be interoperability issues that need to be resolved. There is also the question of regulation compliance – would a maintenance schedule based on data gathered and processed through a digital twin be acceptable to the aviation authorities? Can all consoles support digital twinning, or will some struggle to cope with the amount of data produced? These questions need to be addressed soon, as digital twinning is poised to become a major factor in modern aviation at all levels.

Shaping the Future Through Shared Expertise: FlySight and Europe’s Digital Twin Vision

Beyond the aviation industry, the use of digital twin technology is expanding into the defence domain through pioneering European initiatives such as the EDDI (European Defence Digital Initiative) project, launched by the European Defence Agency (EDA). This comprehensive study explores how digital twins can enhance operational planning, predictive maintenance, and situational awareness across multiple domains — from Air and Land to Maritime, Space, and Cyber.

FlySight, as the lead company of the EDDI consortium, plays a central role in this initiative, combining its experience in augmented reality and simulation technologies with the expertise of key European partners. Through its leadership, FlySight contributes to developing a demonstrator that will showcase how digital twins can revolutionize mission planning and decision-making in complex operational environments — bridging the gap between the virtual and the real world, and paving the way for the future of both aviation and defence applications.